NOx Emissions In Gas Turbine Generators

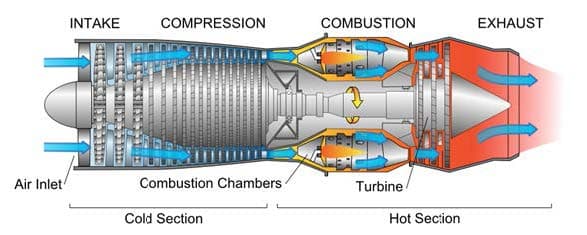

Gas turbine generators are a cost–effective solution for smaller power sources. They provide flexibility and simplicity and are packaged as systems from 20MW to over 1000MW capacity. The gas turbine engine is a proven and reliable technology that allows a complete package to be installed relatively quickly, almost anywhere.

Regulating agencies are reducing emissions standards which further restrict the release of pollutants into the atmosphere, and manufacturers are increasingly developing systems to meet ever tighter standards. In gas turbines, the primary pollutants produced are the oxides of nitrogen (NOx), which result from combustion of fuel in air as well as any nitrogen component in the fuel. The NOx emission of a standard gas turbine is heavily influenced by the turbine firing temperature and the fuel used.

Water injection systems have been developed that directly inject water vapor into the combustor of a gas turbine for NOx abatement. This is accomplished by reducing the flame temperature, which in turn reduces NOx emissions. It was first used on industrial generators as far back as the 1970s.

Demineralized water is directly injected along with the fuel (natural gas, fuel oil, etc.). The water acts to reduce the turbine firing temperature, which directly correlates to a reduction in NOx emissions. Demineralized water is used to minimize scaling and build-up in the nozzles and the combustion chamber. As the load on the generator increases, additional water is used to maintain the turbine firing temperature low enough to reduce NOx emissions to about 25ppm. The turbine flow meter measures the supply water flow rate to the nozzle injector manifold; this is used to control the feed water valve position while monitoring the firing temperature. A very accurate flow meter is required for this precise control scheme and the FT Series turbine meter is an excellent choice with accuracies within 0.1% of reading.

An FT Series turbine meter is used with the LA-5 linearizing electronics. The meter is supplied with an extended range calibration to give a turndown of 100:1 over the flow range. It can be supplied with either meter-mounted or remote-mounted electronics. High temperature amplified pickoffs are used to eliminate noise generated by the floating (non-grounded) electrical system of the turbine generator. The FT Series turbine meter can be placed inside the generator room due to its compact size and durability under extreme conditions.

HIGHLIGHTS

Industry: Power Generation

Service: Flow Rate/Total

Fluid: Water

Application

Adding water to the combustion section of a gas turbine generator to lower firing temperature and reduce NOx emissions.

Problem

Measure supply water flow rate to help control flame temperature.

Solution

FT Series turbine flow meter with high temperature amplified pickoffs and linearizing electronics.

- Reduced ignition temperature

- Reduced NOx emissions

- Optimized flow control

Below are additional resource links for this subject that you may find helpful:

- Turbine Meters

- DB Turbine FT Series – PDF

- Compatible Flowmeter Electronics – Amplifier Link

- Amplifier Link – PDF

Contact your local VMA field engineer today if you need help or have any additional questions.