Rotary Swaging Combines Low Loss with High Flexibility

Cable Selection Today – Always A Trade-off

Most coaxial cables on the market have either a solid or stranded inner conductor, making the selection of a cable assembly a trade-off between lower loss (choosing the solid wire) or flexibility and phase stability (choosing the stranded wire).

The stranded wire cable assembly has higher attenuation compared to solid wire. Well known as the skin effect, the signal only flows in the outermost few microns of the inner conductor, so the signal path in the stranded conductor is longer than in the solid wire. This behavior is more pronounced with microwave signals than at low frequency. Also, the greater contact resistances between the individual strands contribute to higher loss.

On the contrary, microwave cables with solid wire have greater phase deflection with bending than cables with stranded wires, particularly for cable types with a dielectric diameter greater than 2 mm. Here, the cable length is slightly reduced by bending movements, which results in a deformation of the inner conductor. This leads to the phase shift. The effect is caused by interaction with the various construction elements of the cable. To plastically deform the individual wires of a strand, a stronger bending movement is required. The leads to smaller length changes in the overall construct of a microwave cable and to a more stable phase versus bending behavior.

Rotary Swagged Cable Assemblies Meet The Highest Demands In Performance, Reliability and Durability

In order to resolve the trade-off issue facing the coaxial cable market, HUBER+SUHNER combined the advantages of the solid and the stranded wire into one product a low loss, phase stable and flexible inner conductor cable with a long lifetime. To achieve this, HUBER+SUHNER has launched a two-in-one solution, enabled by its patented rotary swaging technology. This technology is unique to the current market and emphasizes HUBER+SUHNER as a leader in innovation and the industry.

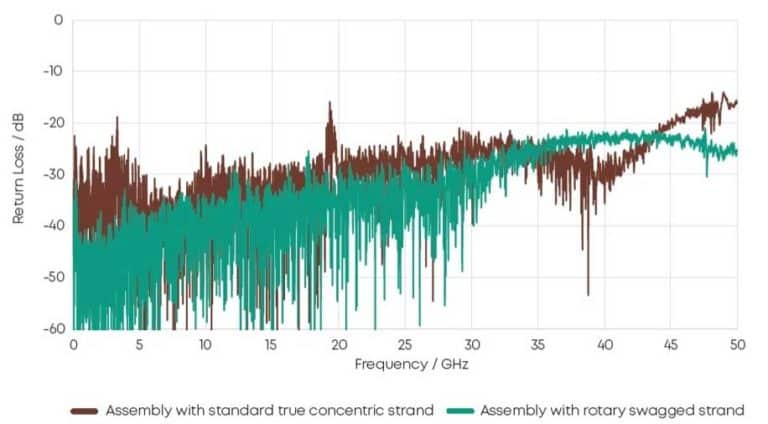

Thanks to the rotary swaging technology, the surface is smoothed and prevents the occurrence of possible discontinuities in the microwave cable, which reduces regular return loss peaks. The conventional stranded wire has a regular structure and is thus more susceptible to return loss peaks caused by changes in diameter and hence impedance. As a result of the changes, part of the microwave signal is reflected. If several discontinuities occur at regular intervals, this results in a strongly reflected signal at a certain frequency-called return loss peak. The rotary swaged stranded wire eliminates this risk by mimicking the signal path of the solid wire and through that improving the return loss level as well. Additionally the contact resistance is reduced when compared with a conventional, true concentric stranded wire leading to a lower insertion loss.

Return Loss Performance

An Innovative Technology With Many Potentials

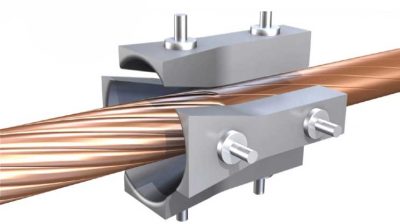

Rotary swaging is a process of mechanical deformation and is achieved by generating repeated blows to a conventional strand. Using hammers, the surface of the strand is smoothened. A nearly perfect round and smooth surface is guaranteed.

This pioneering and unique rotary swaging technology, patented by HUBER+SUHNER in Switzerland, is used for entire SUCOFLEX 500 cable assemblies, it also includes the newly launched 50 GHz SUCOFLEX SSOS assembly – a customizable solution which provides the longest life time currently available on the market.

“The new SUCOFLEX 550S provides an excellent price-performance ratio compared to other solutions available on the market” said Daniel Ulmer, Product Manager at HUBER+SUHNER. Typically, cables will break after a 10-20,000 flex cycles but the SUCOFLEX 550S offers a service life of more than 100,000 flex cycles. Furthermore, it addresses the challenge that customers have had to face in the past to find customized assemblies with short lead times. Previously there had been solutions in standard lengths that were expensive and had a long lead-time, so we are happy to offer a one-stop service that is customizable, affordable and fast. Our SUCOFLEX 500 cable assemblies have all been tested on a high level and are successfully used for test and measurement as well as high-speed digital applications.”

The SUCOFLEX 550S is designed to withstand abrasion, pressure and moisture, making it the go-to assembly for customers looking for precise and long-lasting connectivity solutions. It is available to use in numerous test and measurement applications, including bench-top test ing high throughput RF production testing and for vector network analyzer measurements up to 50 GHz.

Other products in the portfolio which benefit from the rotary swaging technology include the SUCOFLEX 100 series- flexible microwave cable assemblies that offer superior electrical and mechanical performance for static and dynamic applications. HUBER+SUHNER has many years of experience in the development, production and MIL qualification of SUCOFLEX 100 assemblies for airborne, radar and naval applications, Our solutions are used in many systems around the globe and have proven to be reliable and meet the toughest requirements in applications such as fighter jets, helicopters, UAV, radars, phased array antennas, jammers T/R modules and many more.

In addition, the HUBER+SUHNER Spuma RS FR has a low loss inner conductor. This product is the most flexible cable in the Spuma family and features a new TPU jacket material which provides flame retardancy without compromising on flexibility Spuma RS FR is used in radio, tactical and air navigation communication systems as well as in vehicles, marine, airfield and radar applications.

World-Class Service Standard

The SUCOFLEX 500 assemblies guarantee the highest level of satisfaction. Thanks to th que cable and connector design, they deliver the best phase and amplitude stability flexure, movement, temperature and tensile stress, in combination with outstanding re and insertion loss up to 50 GHZ. Due to the rotary swaged low-loss inner conductor an rugged construction, all SUCOFLEX 500 assemblies withstand more than 100,000 flexures without degradation of performance and therefore have a very long service life.

HUBER+SUHNER supplies all SUCOFLEX 500 standard length products within five working days and customized lengths are available within ten working days worldwide.

About HUBER+SUHNER

HUBER+SUHNER offers customers around the globe outstanding products and services for their electrical and optical connectivity needs. We focus on the three main markets of industrial, communication and transportation which are addressed with applications from the three technologies radio frequency, fiber optics and low frequency.

HUBER+SUHNER products deliver high performance, quality, reliability and a long service life – even under the toughest of conditions. A global production network, combined with subsidiaries and agencies in over 80 countries, puts HUBER+SUHNER close to its customers.