What is a Pressure Regulator and Difference Between Various Types?

Pressure Regulators

Pressure regulators are mechanical valves that use feedback to control pressure in both pneumatic and hydraulic systems. There are basically two types of regulators: one regulates upstream pressure (back-pressure regulators) and the other regulates downstream pressure (pressure-reducing regulators).

The pressure is usually contained in a system where fluid is flowing from one place to another through pipes into storage tanks or pressure vessels. A regulator is used to adjust the upstream or downstream pressure from the point where the regulator has been inserted within the system.

They can be as simple as a manually controlled valve to a complex, automated precision system with a pressure sensing element in a feedback loop. The feedback comes from the pressure that is being regulated and this feedback controls the regulator output, either mechanically or electronically.

Mechanical feedback is accomplished using a spring-loaded or pressure-controlled diaphragm, bellows or piston, which controls a valve that acts to increase or decrease the flow through the regulator based on the pressure being regulated. This mechanical regulation of flow acts to control the pressure. In an electronic regulator, the input from a pressure transmitter is used to adjust a valve or valves that control the pressure.

Read ‘What is Pressure? Definition and Types Explained’ for more info.

For the purpose of this post, we will concentrate on pressure-reducing regulators. These regulators reduce a relatively high incoming pressure to a lower outgoing pressure in order to protect sensitive components downstream, or to precisely control a pressure-sensitive process or measurement. Fluid dynamics is a complex subject and tells us that a fluid flowing through a restriction loses energy; pressure-reducing regulators take advantage of this property to regulate pressure.

Pressure in any system is defined as the force per unit area within that enclosed system. Pressure is influenced by the quantity of the fluid present (number of molecules), the volume in which it is contained, and the fluid temperature. Most pressure regulators work to control the number of molecules that are allowed to enter (or exit) the system and thus control the system pressure. Another type, briefly discussed below, is a regulator that controls pressure by increasing the force applied to a closed system.

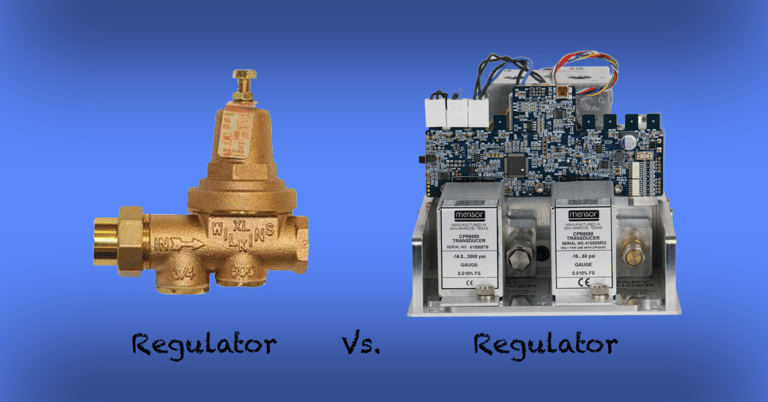

A distinction in the classification and understanding of regulator types can be made between mechanical “industrial regulators” and electronic “precision pressure regulators,” which are also called “precision pressure controllers.” The latter is typically used within precision pressure calibrators. In either case, the same goal of pressure regulation is accomplished and the only difference is the degree of precision and stability achieved.

For the purpose of this discussion, we will make this distinction as follows:

Industrial Pressure Regulation

An industrial pressure-reducing regulator incorporates a valve that is controlled by a spring-loaded diaphragm, bellows, or piston.

The downstream pressure works to push the diaphragm or piston in a way that will permit or restrict the flow through the valve from the upstream to the downstream side of the valve.

The spring tension can be adjusted so the downstream pressure maintains a pre-determined set pressure. Changes in the downstream pressure will automatically adjust the valve to allow or restrict the flow of fluid to achieve the setpoint.

These industrial pressure regulators come in a variety of configurations, depending on the manufacturer. They are the preferred choice in industrial settings because they are robust and self-regulating, which uses the pressure of the system without the need for power input or external sensing elements.

They can be set, left alone and the precision of the pressure control is adequate for most applications. Variations on this design can utilize two valves to help ensure proper regulation in all conditions.

Precision Pressure Regulation

Solenoid Valve Regulators

Another method of pressure regulation, often used within precision pressure controllers in calibration labs, utilize inlet solenoid (electro-mechanical) valves that allow a source pressure to enter the system and outlet solenoid valves to exhaust to atmospheric pressure or a vacuum.

The downstream section of a system is controlled by adding or subtracting molecules of gas. Feedback from a downstream pressure sensor is measured and processed using a control algorithm that opens and closes the solenoid valves to produce the desired pressure setpoint downstream of the valves.

To achieve a very precise controlled pressure, several inlet/outlet valves can be used in tandem that have fine to coarse orifices which can be opened or closed depending on the difference between a setpoint and the downstream pressure and/or the rate at which the pressure is approaching the setpoint. In this type of regulator, an extremely precise pressure can be achieved. The service life of these solenoid valves is affected by the pressure differential applied across the valve. It is for this reason Mensor uses a proprietary system that maintains a nominal differential across these valves to increase their longevity.

Both the Mensor CPC4000 and CPC6050 incorporate this technology in order to provide years of operation with minimal solenoid failure. Solenoid valves are used in a variety of applications and are common in precision control systems. They are also relatively less expensive than their needle valve counterpart.

Needle Valve Regulators

Another regulation method uses two precisely machined needle valves made of a durable ceramic material using a small port and a threaded needle plunger. One valve supplies pressure and the other exhausts pressure from the controlled downstream system. The valves are designed to achieve both fast control and precise control. Valve modulation is controlled using an algorithm that constantly monitors the difference between the downstream pressure, the setpoint, and the rate at which the pressure is approaching the setpoint.

The algorithm controls the needle valves to achieve a precision ramp into the setpoint and constant stability. This type of regulator achieves a high degree of stability in the pressure output which can be affected by temperature changes in the system or any fluctuation downstream. The Mensor CPC8000 uses this method which enables the product to deliver a precise, stable control at pressures up to 6000 psi.

Piston Actuated Regulators

Typically used in hydraulic systems, piston actuated regulators work similarly to deadweight testers by applying a force over a cross-sectional area of a piston within a cylinder.

The pressure is equal to the force divided by the area of the piston, which is the definition of pressure P=F/A. The greater the force applied, the greater the pressure. The Mensor CPC8000-H uses this method to precisely control pressures up to 23,000 psi. The benefit of this type of regulator is its ability to reach very high pressures, which is achieved by reducing the cross-sectional area of the piston.

Conclusion

About Mensor

Since its founding in 1969, Mensor has been dedicated to designing and manufacturing the finest, high-accuracy, pressure measuring, calibration, controlling instruments and test systems available. Through the years, Mensor has developed an international reputation for quality products and service in the precision pressure instrumentation market.

Since 2006, Mensor has been a part of the WIKA Group, allowing an expanded product portfolio. Historically, Mensor is known for pressure. Now, with the addition of the brands Degranges-Hout, DH-Budenberg and ASL, Mensor offer temperature products, primary standards and process tools including digital pressure gauges, indicators, pressure controllers, hand-held calibrators, primary standards precision pressure transducers, pressure generators, reference thermometers, portable temperature calibrators, resistance thermometry bridges, calibration baths, engineered systems, digital barometers, air data test and more.

Mensor is located in San Marcos, Texas, between Austin and San Antonio in central Texas. The 45,000 sq. ft. facility includes all manufacturing, engineering, accounting and sales departments.